About Us

Borok distillery was founded back in 1891. Its location is 14 Myru Street, Borok village, Sokal district, Lviv region.

On December 29, 2020, LLC «CLIMITED PLUS COMPANY» purchased Borok «Ukrspirt» SE at the auction of the Regional Department of the State Property Fund of Ukraine.

BorokSpyrt was launched on March 18, 2022, after its reconstruction and today it is a modern production facility for high-quality ethanol and advanced processing of dry distiller’s grains.

We are an industry leader thanks to our fully automated production process, designed as follows:

RECEIVING PIT

designed for unloading raw materials and further moving to the loading elevator on the process line

RAW MATERIALS WAREHOUSE

BSH GRAIN SEPARATOR

grain cleaning from impurities that differ in geometric dimensions and aerodynamic properties

A1-DM2R HAMMER MILL

designed for grain crushing

BREWING VAT

designed for brewing mash from crushed grain and water

STEAM BOILER (UL-S-IE 6000*13 bar)

designed for supplying process steam to manufacturing facilities for various purposes

WATER SOFTENING PLANT

designed for water treatment in the supply systems of water and steam boilers

SPIRAL HEAT EXCHANGER

designed for recovering process heat with spiral heat exchangers

Application of the continuous process of HYDRO-FERMENTATIVE MASH TREATMENT

YEAST-GROWING VAT

designed for the yeast cell cultivation

FERMENTATION PLANTS

designed for starchy raw materials bioconversion

GRAIN-BASED RECTIFICATION PLANT

designed for producing high-quality ethanol, consisting of an grain column, ejection column, rectification column, finishing column, impurity concentration column

MODERN LABORATORY EQUIPMENT

for technological and chemical production testing

ETHANOL STORAGE AND SHIPMENT

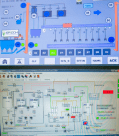

EXCELLENT AUTOMATION OF TECHNOLOGICAL PROCESSES

AIR COMPRESSOR

designed for air compression with further supply under pressure

SOLID FRACTION COLLECTOR

Stage 1 – Mechanical separation on ОГШ-321 centrifuges into a solid fraction and liquid fraction with suspended particles

FLOTTWEG

Stage 2 – Sedimentation of suspended particles of the liquid fraction using high-speed centrifuges (Flottweg)

ULTRA-FILTRATION

Stage 3 – Thickening of suspended particles of the liquid fraction using an ultra-filtration plant

NANO-FILTRATION

Stage 4 – Purification of the liquid fraction at the nano-filtration plant resulting from the ultra-filtration plant

DRYING

Stage 5 – Solid fraction after ОГШ-321, concentrate after Flottweg, and concentrate after ultra-filtration are fed to the mixer and then to the dryer. When drying is done, we get DDGS (native distiller’s grains)

Shipping

- DAP

Payment

- Individual approach to each customer

- Cashless payment

- Wholesale

Email us

Thank you. Request accepted

A manager will get back to you shortly